Description

Benefits & Features:

- Improved Productivity

- High speed gun motor control for fast open / close

- High acceleration SRA robot for quickest movement between welds, SRA robots are the world’s fastest in their payload class

- Extensive product line

- SRA comes in various payloads from 100kg to 240kg

- Standard floor mount models, invert mount model, long reach models over 3 meters.

- New hollow arm series for internal dress of spot welding utilities provides extra protection and minimized stress for utility lines (cooling water, weld power, signals, servo gun cables)

- Improved Weld Quality

- Pressure calibration up to 10 points for more accurate pressure through the spot welding range

- Nachi’s integrated spot weld timer, AC and DC versions available now. Full programming from the robot teach pendant, weld results storage for traceability, full integration for fastest possible communication.

- Spot weld solutions for aluminum parts

- Long tip life between dress cycles (>400 welds)

- EXCLUSIVE robot mounted SEAM WELDER

- Reduce part weight with the same strength using continuous welds

- Reduce the amount of high strength steel, lowering costs

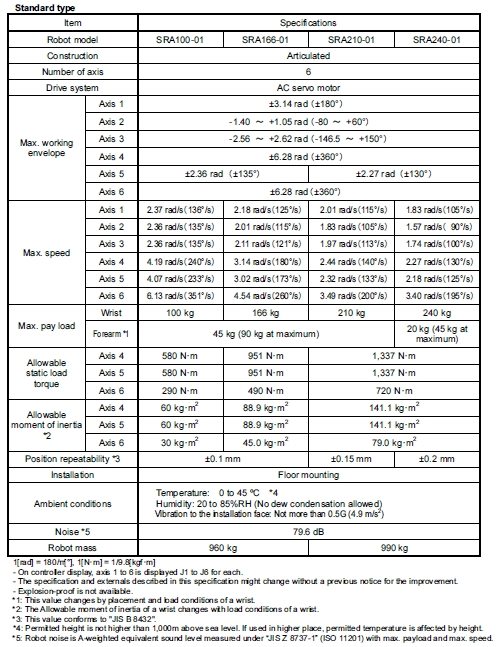

SRA210 General Specifications

Additional Specifications with A-Trac Cable Managment System Option Installed

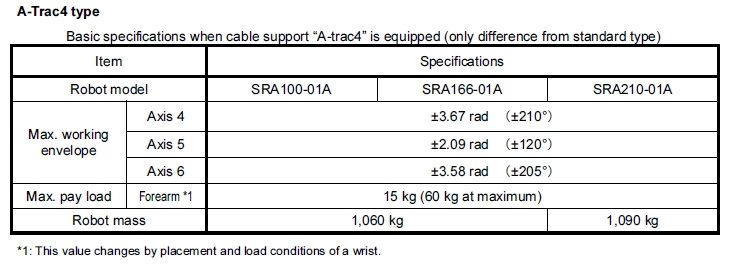

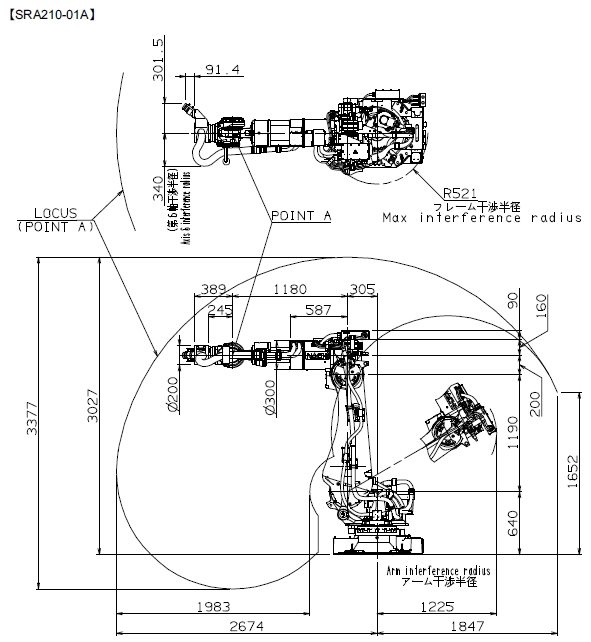

Robot Dimensions and Working Envelope

Robot Dimensions and Working Envelope with A-Trac Cable Management System Option Installed

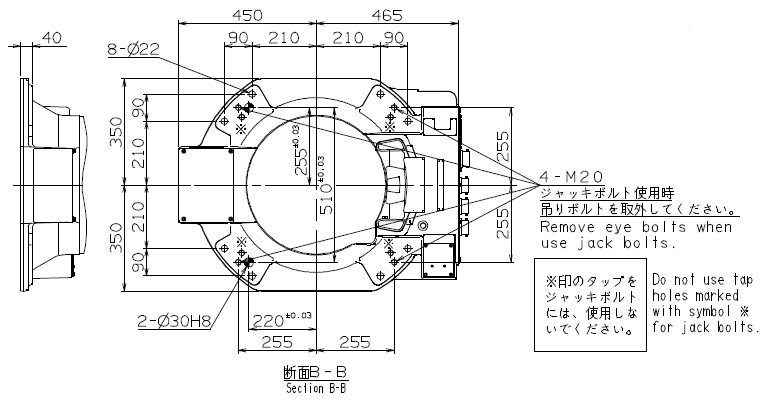

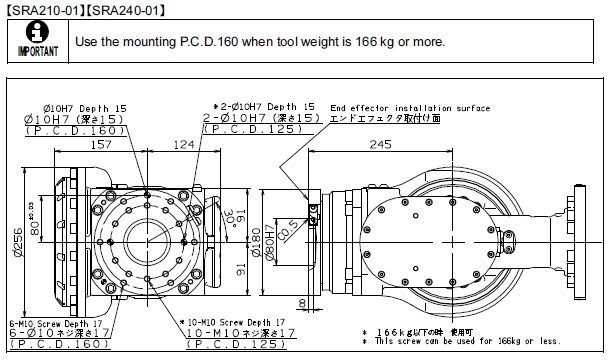

Faceplate Hole Pattern for Mounting End of Arm Tooling

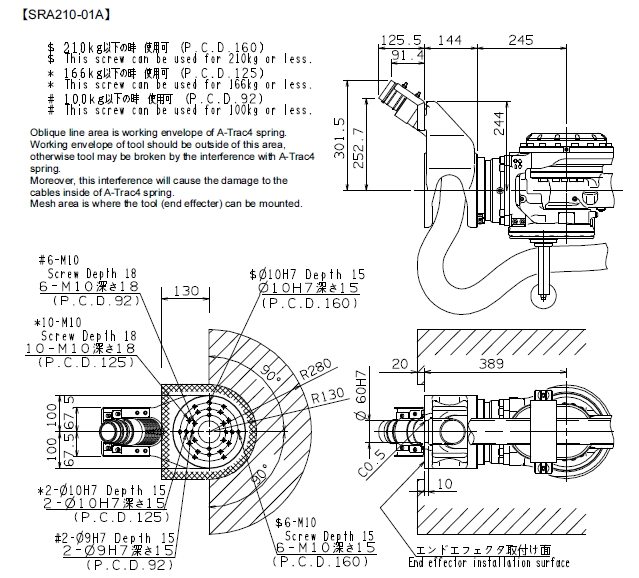

Faceplate Hole Pattern for Mounting End of Arm Tooling with A-Trac Cable Management System Installed

Baseplate Mounting Information and Robot Footprint