Description

- Space-Saving Installation: Wall-mountable without obstructing machine access or fixture openings.

-

High-Speed Operation: Fast axis speeds for increased productivity.

-

Powerful Wrist: Double the torque of the MZ12H for heavier tooling.

-

Cleanroom Ready: IP67-rated arm and Class 4 cleanroom compatibility for contamination-sensitive environments.

-

Flexible Applications: Ideal for board transport, assembly, material handling, and precision inspection.

The MZ12W is built to improve workflow efficiency, reduce floor space requirements, and enhance machine accessibility—all without compromising on strength or accuracy.

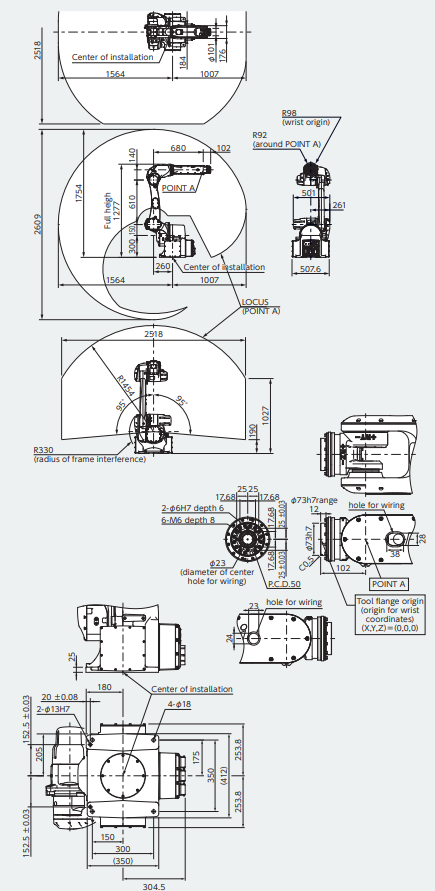

MZ12W Dimensions and Operating Range

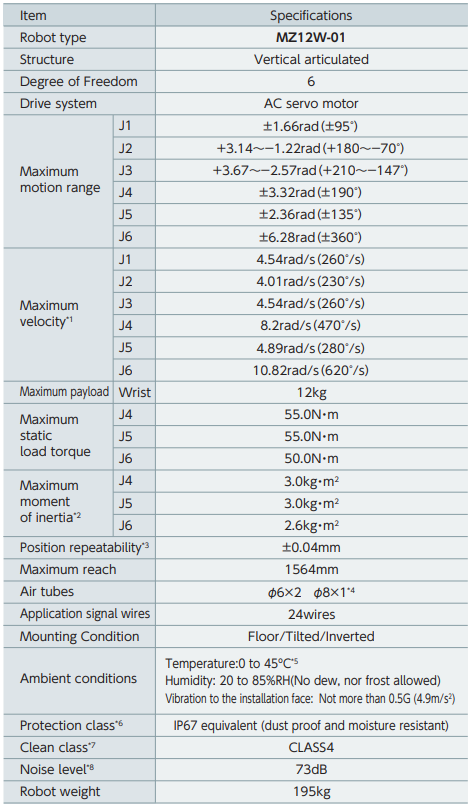

MZ12W General Specifications

- The maximum velocity in the chart is the maximum value. It will change

depending on the operation program and the wrist load condition. - Maximum moment of inertia of a wrist changes depending on the load

condition. - JIS B 8432 conformance.

- When selecting the built-in solenoid valve of clean specification,

air tube is φ6×1. - Using at 1000m or lower sea level. Ambient temperature has limitations

when allowable altitude is exceeded. - Liquid such as organic compound, acidity, alkalinity, chlorine or gasoline

cutting fluid which deteriorates the seal material is not available to use.

The wire-harness portion is IP65 equivalent, and the robot controller

CFDs-3000 is IP20 equivalent. See the figure of “Protection class” below. - Based on internal assessment in accordance with ISO14644-1. To ensure

cleanliness, install the robot in a clean room with downflow. The robot is

not packed in a dustproof package, so dust removal and wiping and

cleaning of the robot is required when bringing it into the clean room. - Robot noise is A-weighted equivalent sound level measured under

“JIS Z 8737-1”(ISO 11201) with maximum payload and maximum velocity.