MR20

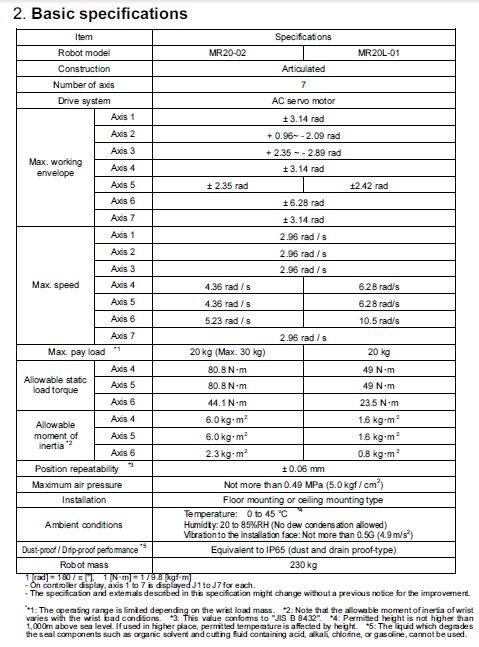

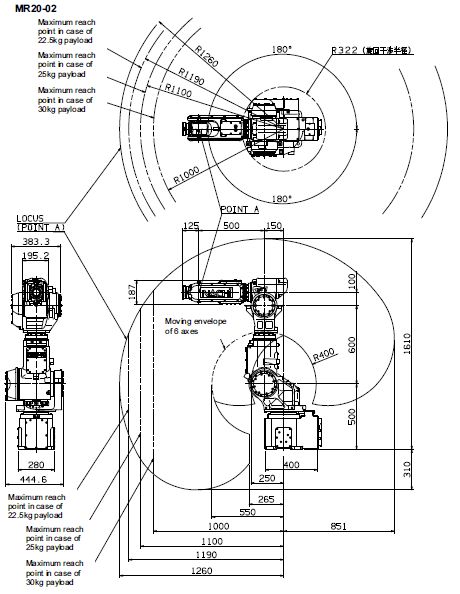

Unique 7-Axis design distinguishes the MR series from other robotic products by providing increased freedom of motion and achieving optimum robot posture at all times. The 7th axis allows the MR series to avoid singularities by providing multiple arm posture solutions for a single working TCP. The innovative design structure offered by the MR series makes it excellent for machine tending applications allowing the robot to be placed to the side of the machine, providing an open front for machine maintenance. The MR20 provides an impressive 1260mm of reach at 20Kg payload or up to 30Kg if using a 1000mm envelope. Floor and Invert mounting solutions are available to maximize work cell flexibility and reduce the automation floor space required. MR series robots are also capable of working cooperatively to perform complex assembly tasks boasting an impressive ± 0.06mm repeatability. When combined with a robot slider the MR series can tend many machines using a single robot, drastically reducing automation costs. To see examples of the MR series robots in use please visit our YouTube Channel or click the youtube video links.

____________________________________

Brochure (PDF)

Detailed Technical Specification (PDF)