Description

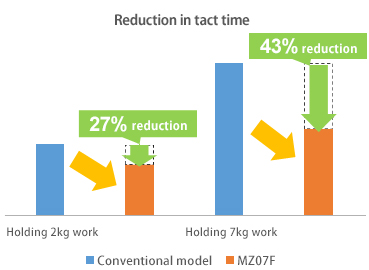

High speed – Increased Productivity

The world’s top-class speed on each axis remains unchanged. Up to 43% * shorter tact time than conventional models due to improved acceleration/deceleration performance.

High accuracy – appliable to complex work, reduction intact time

Improved pose repeatability can handle complex operations. Enhanced path accuracy for tact time reduction. Pose repeatability: Reduced misalignment to approx. 3/4* of conventional robots Path accuracy: Reduced misalignment to approx. 1/3* of conventional robots

Hollow wrist structure – space saving

Wiring for tooling can be routed through the hollow wrist to minimize the risk of interference with peripheral equipment, allowing flexible operation even in small spaces.

Wiring for tooling can be routed through the hollow wrist to minimize the risk of interference with peripheral equipment, allowing flexible operation even in small spaces.

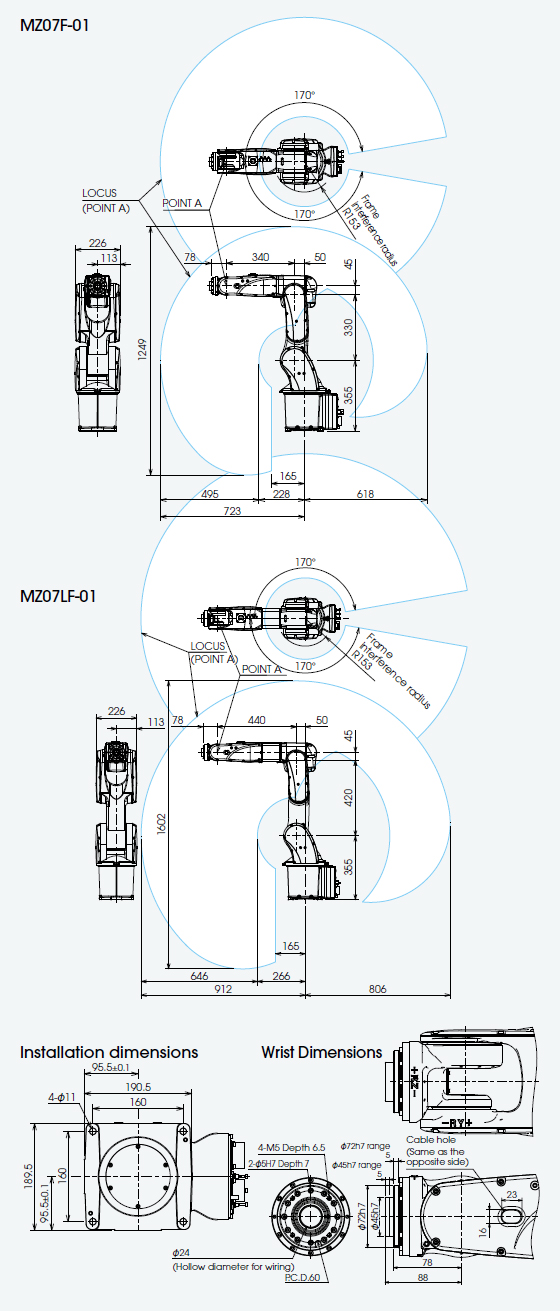

MZ07F & MZ07LF Dimensions and Operating Range

(*1) The specifications are subject to changes without notice.

(*2) In case that an end user uses this product for military purpose or production of weapon, this product may be liable for the subject of export restriction stipulated in the Foreign Exchange and Foreign Trade Act. Please go through careful investigation and necessary formalities for export.

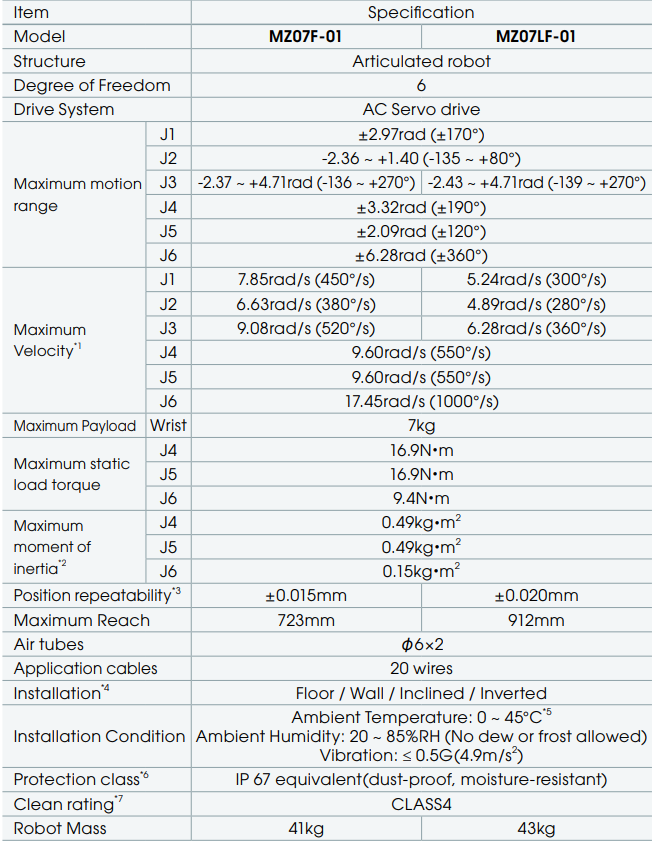

MZ07F & MZ07LF General Specifications

1[rad]=180/π[°], 1[N・m]=1/9.8[kgf・m] *Explosion-proof version is not available.

*1 The maximum velocity in the table is the maximum value and varies depending on the operation program and wrist load conditions.

*2 Please note that the allowable wrist moment of inertia depends on the wrist load conditions.

*3 JIS B 8432 conformance

*4 The operating range is limited when mounted on a wall or tilted. (Example: #1-axis operating range is ±30° for wall mount)

*5 Using at an altitude of 1000m or less. Ambient temperature limited when the allowable altitude exceeds.

*6 A liquid that deteriorates the sealing such as organic solvent, acid, alkali, chlorine-based, or gasoline-based cutting fluid cannot be used.

*7 This is based on an in-house assessment that complies with ISO 14644-1. In order to ensure cleanliness, install the robot in a down-flow type cleanroom. The robot is not in a dust-proof package. Before bringing the robot into the clean room, dust and dirt must be removed and wipe it clean.