Description

Compact Footprint & Maximum Efficiency

-

Features the smallest turning interference radius and installation area in its class.

-

Lightweight, space-saving design enables flexible installation even in space-constrained environments.

-

Perfect for multi-robot cells and compact automation layouts.

Designed for Harsh Environments

-

Comes standard with anti-corrosion treatment and anti-coolant coating.

-

Rated IP67 for dust-tight and water-resistant protection—ideal for wet, dirty, or chemically exposed work areas.

High-Speed, High-Precision Performance

-

Delivers fast, accurate motion for enhanced cycle times and increased productivity.

-

Rigid structure ensures repeatable precision across a wide range of tasks.

Integrated Smart Cable Routing

-

Hollow wrist design enables internal cable routing to reduce external interference.

-

Cleaner setups and reduced risk of cable wear, perfect for dense work cells or robotic arms operating near other equipment.

Looking for a powerful, compact, and reliable robotic solution?

The MZ35F combines cutting-edge performance with a rugged design, making it one of the most versatile robots in its class.

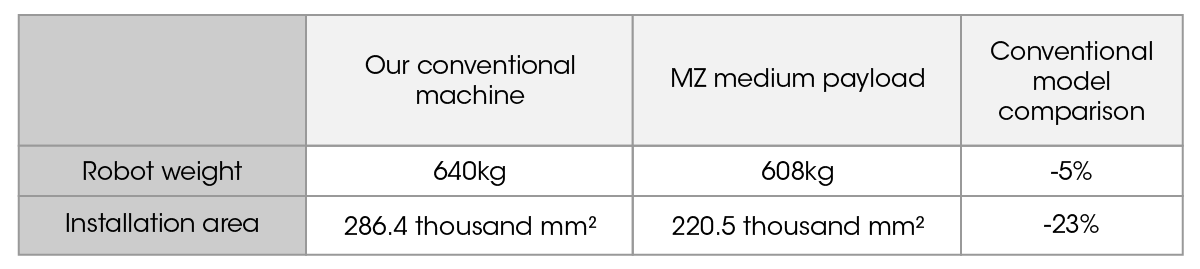

Lightweight and Slim Body

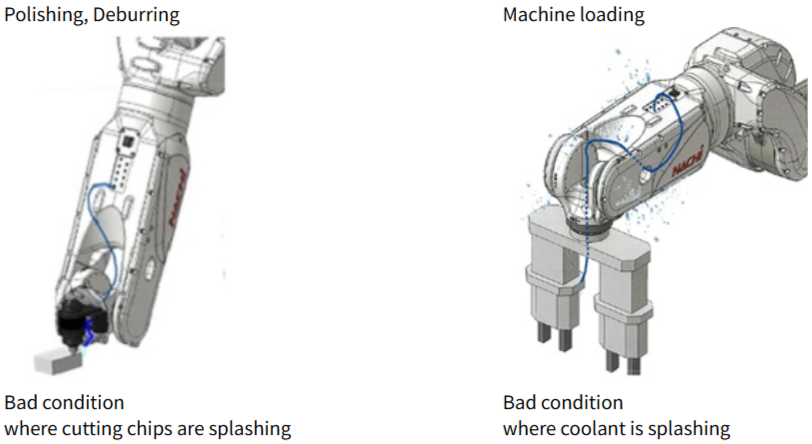

The lighter weight of the main unit (body weight compared to conventional models: -5%) and compactness (installation area compared to conventional models: -23%) makes it easier to consider peripheral equipment. 7 equivalent for the main body is standard specification, expanding the range of applications. It can be used with confidence even in harsh environments where chips and coolant are scattered.

Application Examples

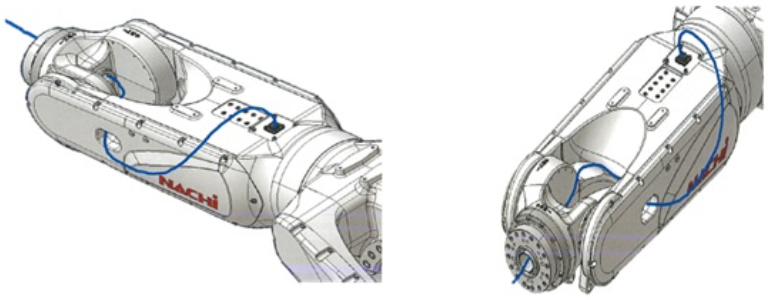

Hollow Wrist

Interference is avoided by routing wiring through the hollow wrist. Flexible operation even in narrow spaces.

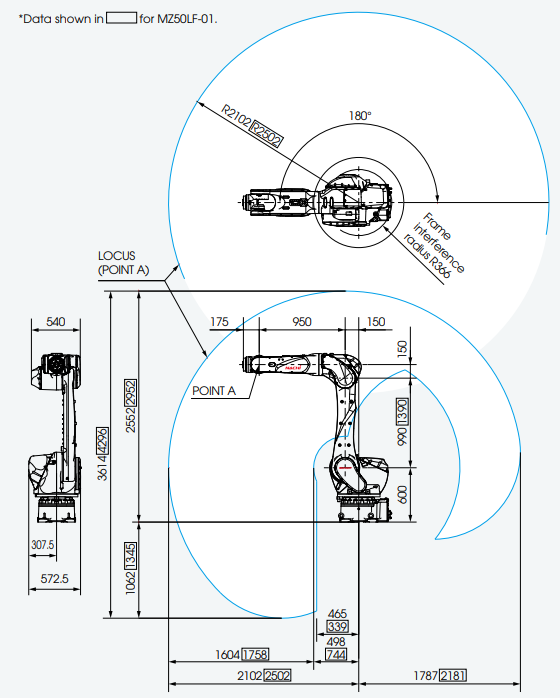

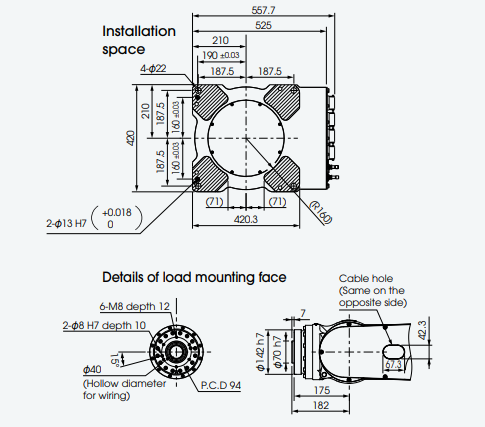

MZ35F Dimensions and Operating Range

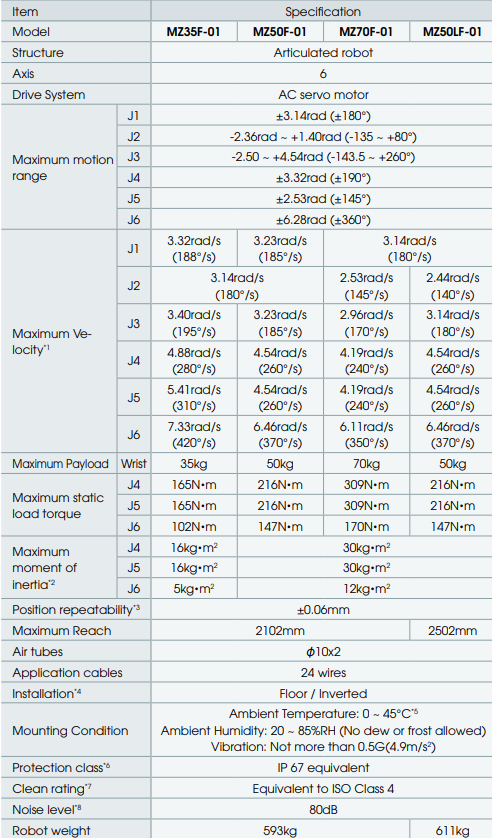

MZ35F General Specifications

1[rad]=180/π[°], 1[N・m]=1/9.8[kgf・m]

* Specifications are subject to change without prior notice for technical changes.

* Explosion-proof version is not available.

- The maximum velocity in the chart is the maximum value.

It will change depending on the operation program and the wrist load condition. - Depends on wrist load condition.

- JIS B 8432 conformance.

- Motion range is limited when wall mount and tilted mount. (Example; axis 1 motion range

is ±30° in case of wall mount) - Using at 1000 m or lower sea level.

Ambient temperature has limitations when allowable altitude is exceeded. - Fluids that cause the deterioration of sealants, such as gasoline-based cutting fluids,

chlorine, alkali, acids, and organic solvents, cannot be used. The wire-harness portion is

IP65 equivalent, and the robot controller is IP20 equivalent. - This is based on an internal assessment in accordance with ISO 14644-1.

To ensure a cleanliness, install the robot in a down-flow type cleanroom.

The robot’s packaging is not dust proof. Before bringing the robot into a cleanroom, you

must clean the robot by wiping it off or by removing dust and fine particles from it. - Robot noise is A-weighted equivalent sound level measured under “JIS Z 8737-1” (ISO

11201) with maximum payload and maximum velocity.